ROTOsoft is a machine designed and built to produce high bulky yarn. The ROTOsoft was born from the continuous research of Giesse and the experience accumulated over the years for fancy and chenille yarn machines up to design a new machine that would produce an innovative yarn was the ROTOSOFT. The ROTOSOFT can work from roving to one color or two colors, thanks to the increased diameter stripping roller can treat long and short fibers with the same quality. Every 4 time the Rotosoft is able to produce different yarns.

Description

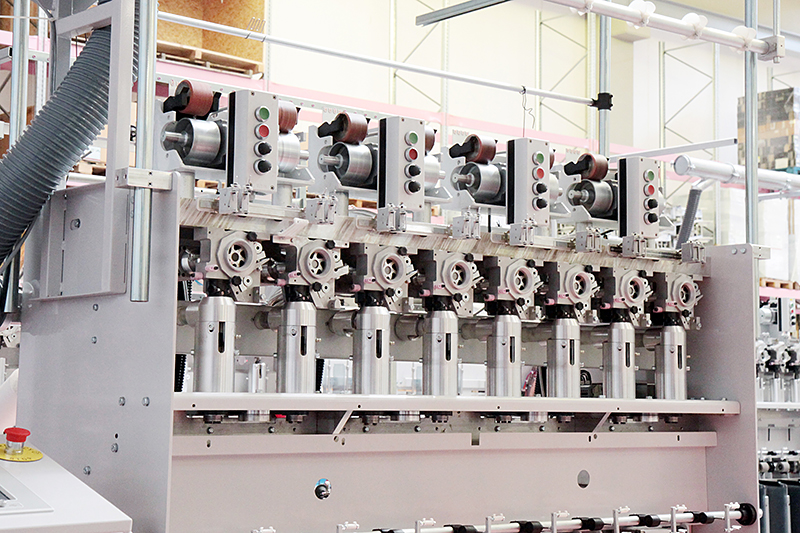

Ongoing research into original and innovative systems for the production of fancy yarns, in particular high-bulk yarns, led to the design and construction of the new ROTOSoft.

ROTOSoft is a machine designed and built to produce HIGH-BULK type fancy yarns in up to 2 colors with an innovative method. The yarn is made up of two basic elements: a woven mesh container (tubular sock) produced with a special needle head (hosiery type) and an effect wick which can be of any type up to two colors at the same time.

The sliver effect may be fed by roving-frame cops, finisher bobbins.

The sliver is opened by a carding action and inserted by drawing into the stocking being formed.

The thread thus constructed is twisted by the ring-traveller system and wound-up on the spindle tubes.

The ring rails are independent among the various sections and allow different doffing times among the different sections in such a way that the machine, consisting of various work modules, is always functioning, excluding the turn of the work module for which the doff is ready.

Advantages:

- Maximum volume of yarn of the same count.

- Maximum elasticity and softness of yarn.

- High degree of covering.

Individual motorized spindles for minimum energy consumption.

Advantages:

- Maximum precision in controlling the speed of each individual spindle, independently of the weight of the cop.

- Elimination of components and ventilation of mechanical drive of the spindles.

- Improvement in yarn quality.

- Reduction of energy consumption per Kg of product.

The machine is modular: subdivided into sections of 8 combined spindles up to a maximum of 12 sections (96 spindles).

La ROTOSoft, as well as producing high-bulk yarns, can also make plain or fancy tapes, can produce yarns that are caged or caged and twisted in the same operation or, with suitable customizations, cut or entangled. In this way each Customer can choose, with one machine only, the most suitable field of production for his requirements in the sector of classic yarns, fancy for knitwear, for furnishings, weaving or clothing.

Technical Specifications

- Gauge: 180 mm

- Number of spindles per module: 8

- Maximum number of spindles per machine: 96

- Sizes of spindle tubes: 37.7 mm x 31 mm x 455 mm, (On request to Customer’s design)

- Range of producible counts: from 0.5 Nm to 15 Nm

- Double-drop needle heads.

- Maximum speed of double-drop needle head: 2,100 rpm

- Maximum mechanical speed of insertion of the core of the machine: 200 m/min

- Maximum mechanical speed of production: 75 m/min

- Production speed: in function of yarn type

- Maximum mechanical speed of spindle rotation: 8,500 rpm

- Feed: effect fibres up to 2 slivers up to 2.5 gr/m

- Ring type and diameter: Conical Type 115 mm (4.5”), 127 mm (5”), 140 mm (5.5”)

- Installed power: 4.2 kW/module