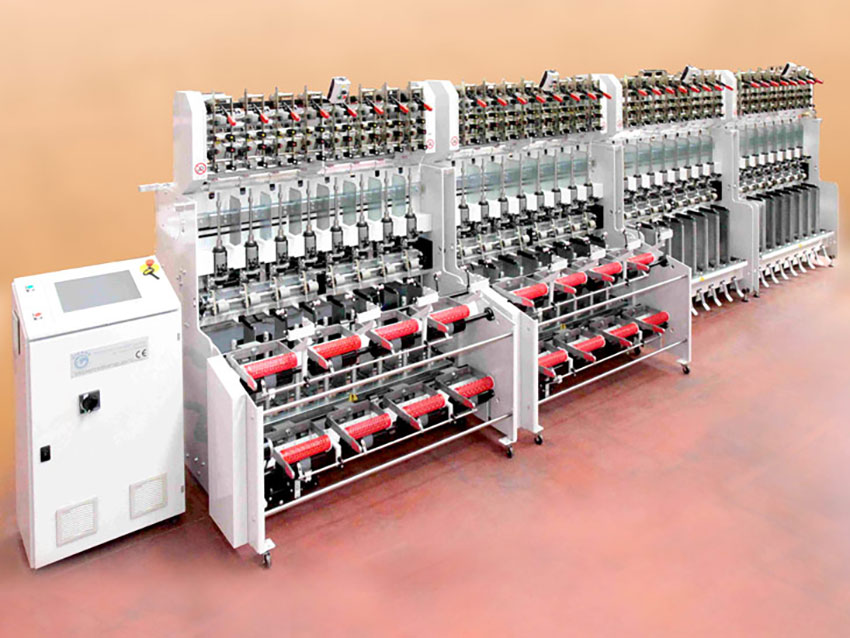

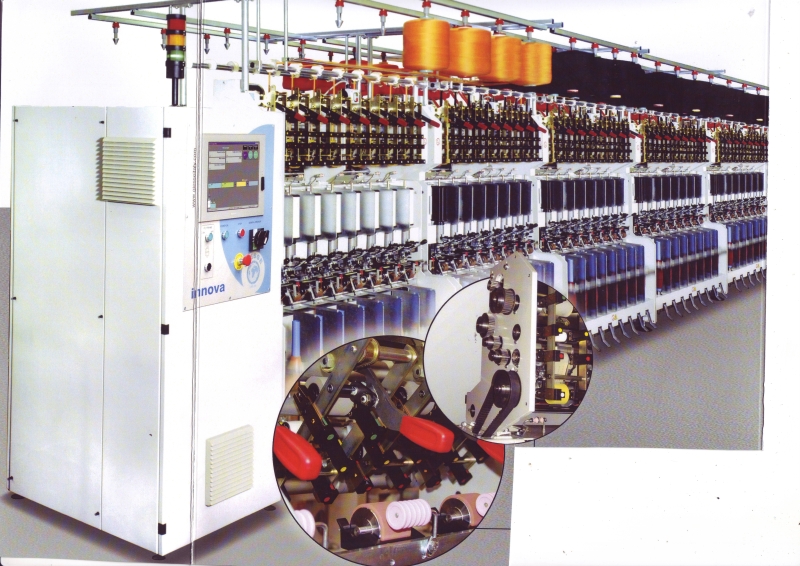

INNOVA is a machine designed and built to produce specialty high quality fancy yarns. Innova can process yarn (Model MF) or roving/finishing (Models MS1-2). Thanks to the modularity of the project, a single machine can produce yarns from yarn to roving/finishing and also have the possibility to prepare some modules with take up on bobbins and others with take up in cops. Thanks to its modularity, the customer can start producing fancy yarn with minimal investment of money and in the future decide to extend the same machine adding more modules also with different configurations that meet the interest of the market.

Description

INNOVA is a machine designed and built to produce fancy yarns setting out from thread or roving, wound-up on cops or cone.

On the basis of the type of feed and the type of drafting unit the machine setups are:

- INNOVA MF with thread feed;

- INNOVA MS-1 with feed from roving or cans with one drafting head,

- INNOVA MS-2 with feed from roving or cans with two drafting heads.

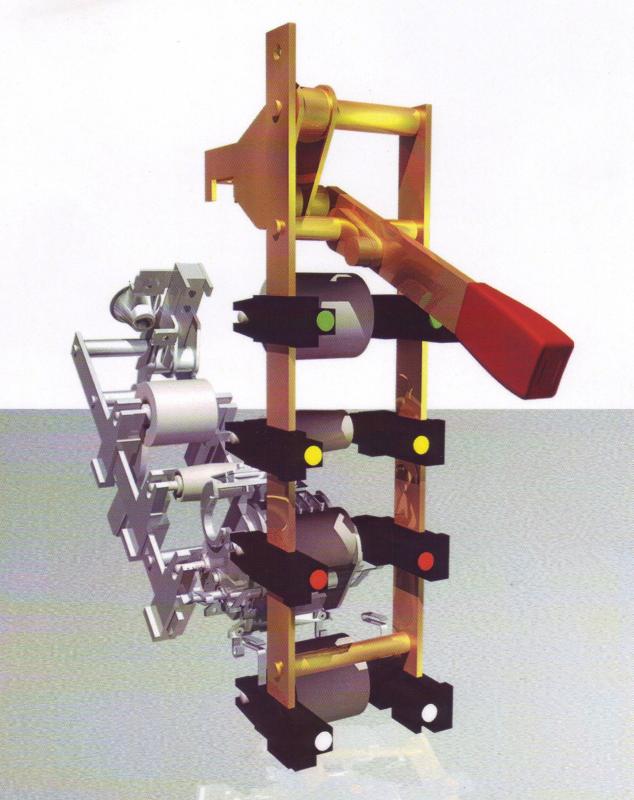

The thread produced can be tied with a continuous filament (hollow-spindle) or, with a special setup, inserted into a net stocking (needle head).

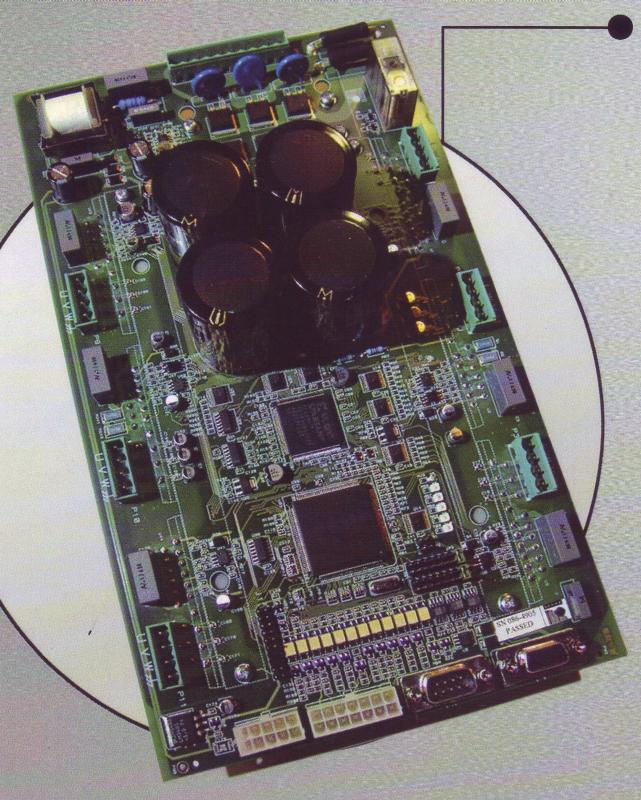

INNOVA may be equipped with an electronic “yarn guard” in each individual production position.

The standard wind-up of the yarn is on a spindle tube. With an additional unit, external to the machine but part of it, the yarn can be wound-up on winder tubes, cylindrical or conical.

The machine is modular: subdivided into sections of 8 positions of combined spinning up to a maximum of 21 sections (168 spindles)

Each section of eight spindles is equipped with a tangential belt for driving the binding device and a tangential belt for rotation of the spindles.

The electronic system of drive and control set on the main head, controls with a touchscreen each section of 8 spindles independently one from the other to permit different work processes in terms of quality and/or colour on the various sections.

The ring rails are independent among the various sections and allow different doffing times among the different sections in such a way that the machine, consisting of various work modules, is always functioning, excluding the turn of the work module for which the doff is ready.

Advantages:

- Easy management of the yarn production parameters.

- Optimisation of the production parameters with ongoing adjustment thereof.

- Reduction of energy consumption per kilo of product.

Technical Specifications

- Gauge: 160mm with ring 115 mm (4.5”); 180 mm with ring 140 mm (5.5”)

- Number of yarn per module: 8

- Max number of yarn per machine: 168

- Range of producible counts: up to 30 Nm

- Range of twists: 9,999 T/m (in function of yarn type)

- Sizes of spindle tubes: 42 mm x 34 mm x 450 mm

- Ring type and diameter: Conical Type 115 mm (4.5”), 127 mm (5”), 140 mm (5.5”)

- Maximum mechanical speed of machine (production): 35 m/min

- Maximum mechanical speed of overfeeding: 70 m/min

- Production speed: in function of yarn type

- Installed power: 3.5 kW/module

- Feeding sliver from cans up to 5 gr/m

Version with hollow-spindle

- Top speed of hollow-spindle: 14,000 rpm

Version with needle head

- Top speed: 2,100 rpm

Version for wind-up on tubes

- Tube sizes for cylindrical tubes: diam. 62 mm x 230 mm

- Tube sizes for conical fubes: diam. 73 mm x 230 mm, Conicity 5°